Dual lead worms and Worm Gears

Product Introduction

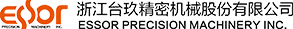

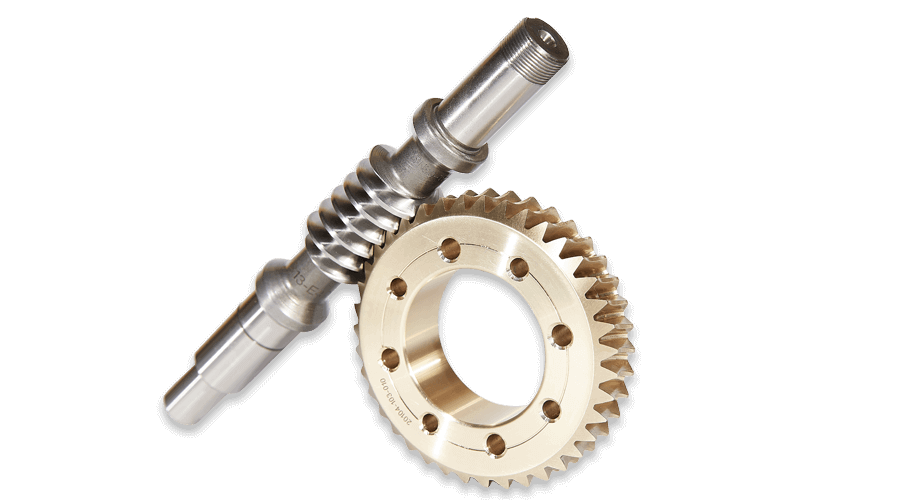

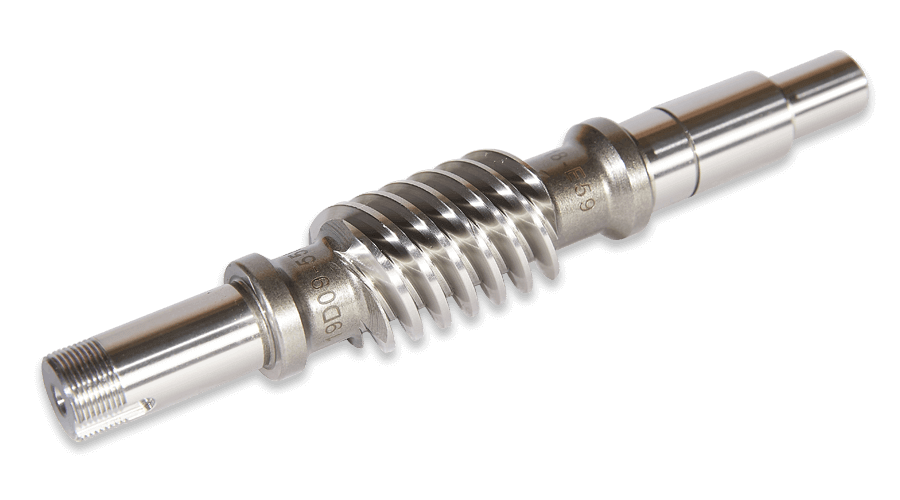

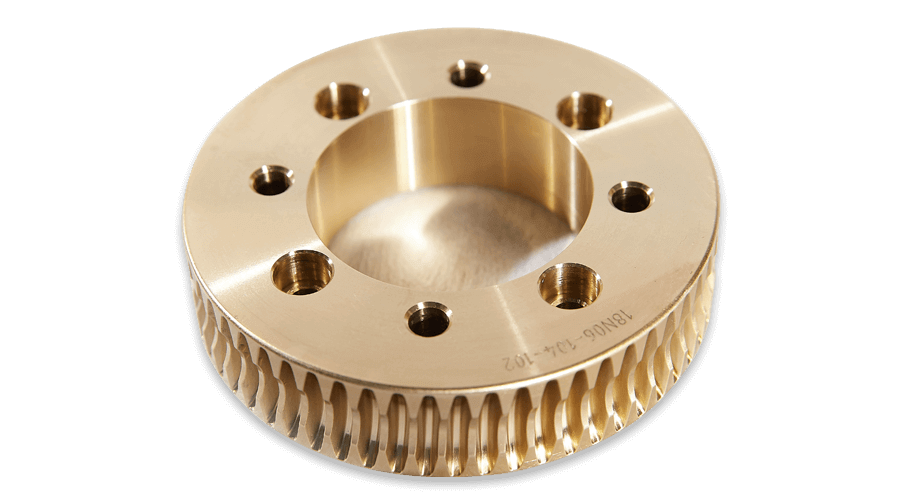

Dual lead worms and worm gears

The dual lead worm can move in an axial direction for a certain amount when meshing with a worm gear to reduce backlash close to zero to increase the accuracy. The dual lead worm can be adjusted when necessary during the operating life of worm gears to increase its life expectancy compared to the split worm type.

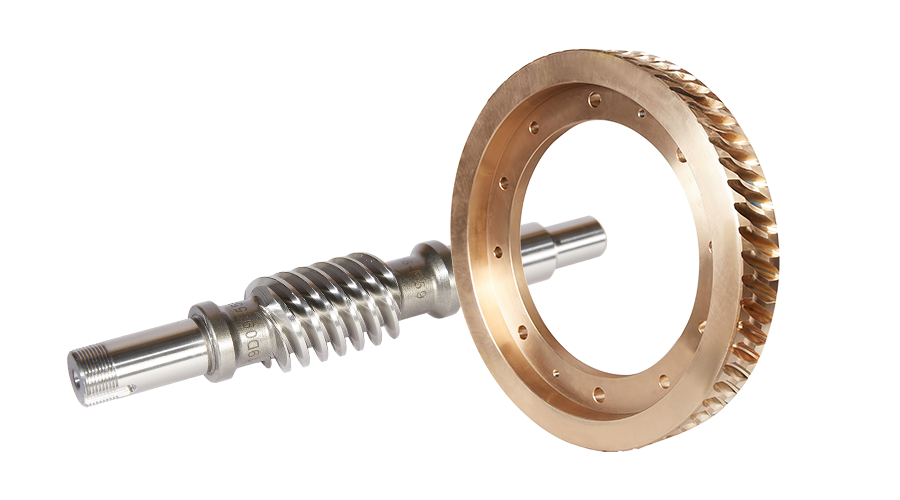

Dual lead worms and dual lead worm gears with low backlash and backlash adjustable are widely applied in CNC rotary tables, cutter drives, machining tools positioning structure, heliostats drive for concentrating solar power, and dual lead worm reducers for smart production.

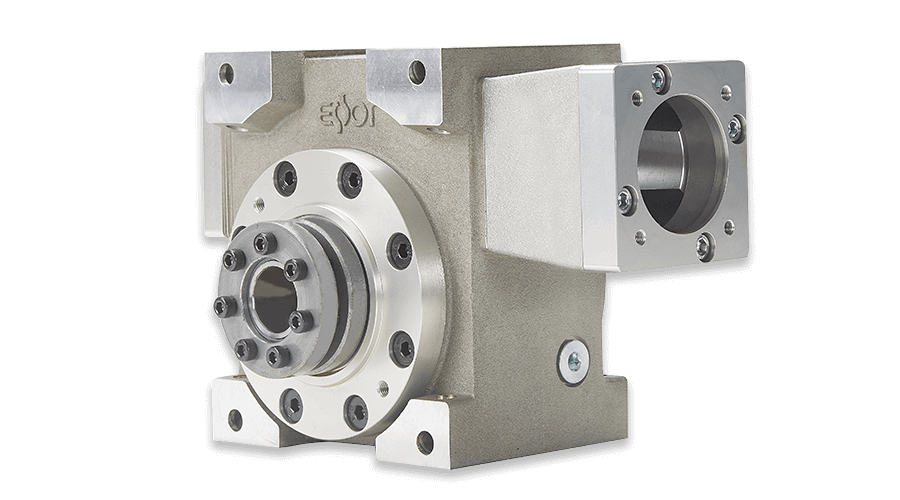

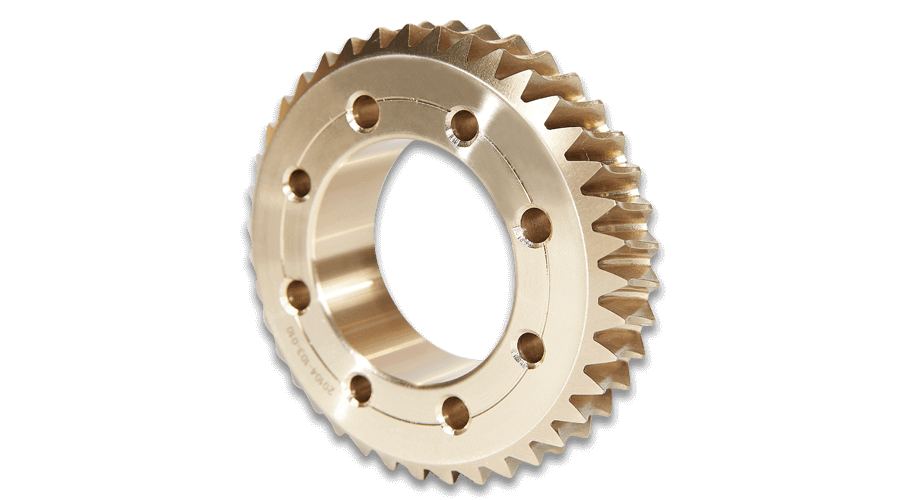

Essor has the specialty to manufacture dual lead worms and worm gears, the technology as well as precise processing knowledge are instructed by doctorate professors of mechanical engineering from Taiwan, we concern about the relationship between worm gear geometry and hobbing process to increase accuracy. The accuracy of our worms and worm gears can be made up to DIN 2.

The dual lead worms and worm gears we manufactured for rotary tables with faceplate diameters 125, 170, 255, 320, 400, 500, 630 and 800 are available for choices.